At Tusco, our drive to find a better way has made us a trusted resource in wooden-component manufacturing. We have taken the restrictive, luxurious wooden designs of the past and transformed them into accessible, cost-effective, and polished mixed-media pieces for our customers. The sturdiness and visual appeal of wooden components can elevate the look for your project.

We understand the expectations of our clients and strive to exceed them. Because we engineer and produce custom components in-house, we can provide fast turnaround times, low costs, and responsive communication throughout the whole process.

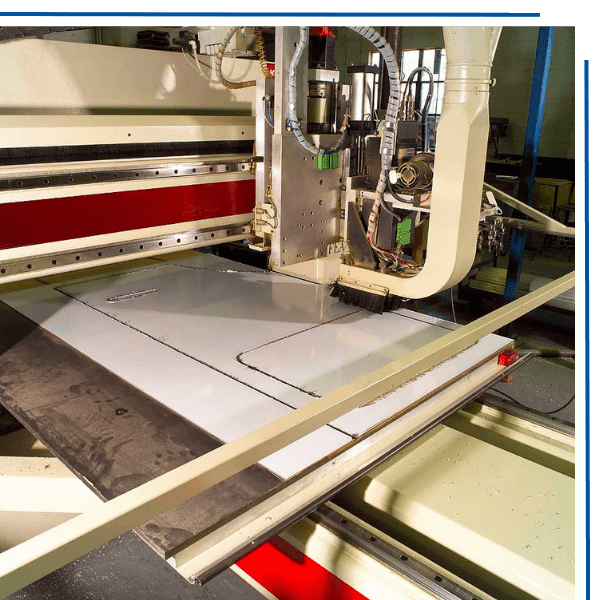

Our exceptional in-house capabilities create a sustainable production process for your custom, mixed-media piece. Wood parts for your fixture can be cut automatically using our computerized Komo VR Mach One S router. To set pieces apart, we are equipped with an edge-bander to apply matching laminate edges.

Edge banding improves the life and investment in your project by physically reinforcing it with laminate edges to offset wear and tear. By applying a trim to the raw wood edges of a piece, your project’s cohesive and attractive finish draws the eye and brings attention to your product. Our edge-banding process ensures that custom pieces are more accurately duplicated over time, which saves time and money for our clients.

We are specially equipped to process three-mill edge banding with routing, drilling, and hardware insertion. Product and quality managers trust us to bring their pieces from concepts to flawless, finished products.

Our solutions are tailored specifically to your project.

Custom laser cutting with our Trumpf Trulaser 5030 laser.

Varied brake presses provide the perfect form.

Fabricated tube assemblies are custom formed and joined.

We produce intricate wire components quickly and without tooling costs.

Certified MIG and TIG welders are supplemented by robotic welders.

Powder coating protects your product and sets it apart from the competition.

Custom cut, shaped, or fabricated plastic components provide mixed-media dimension.

Our on-site warehouse is available to allow us to directly drop ship your project anywhere.

Everything from screenprinting to packaging can be done before shipping your project out.